Focus on R&D of High-Precision Micro-Hole Processing and Laser Cutting Technology

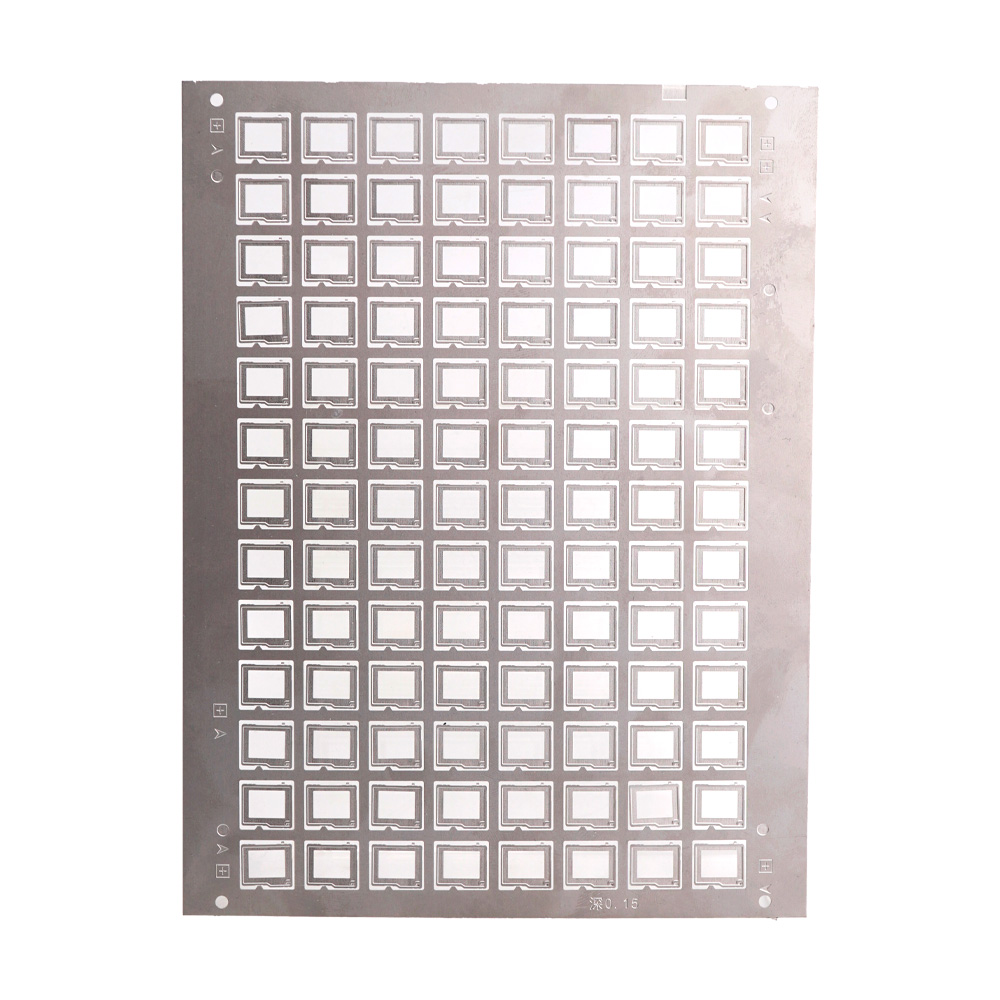

The camera module bracket is a micro metal structural component that fixes and accurately positions core optical elements such as camera lenses and se...

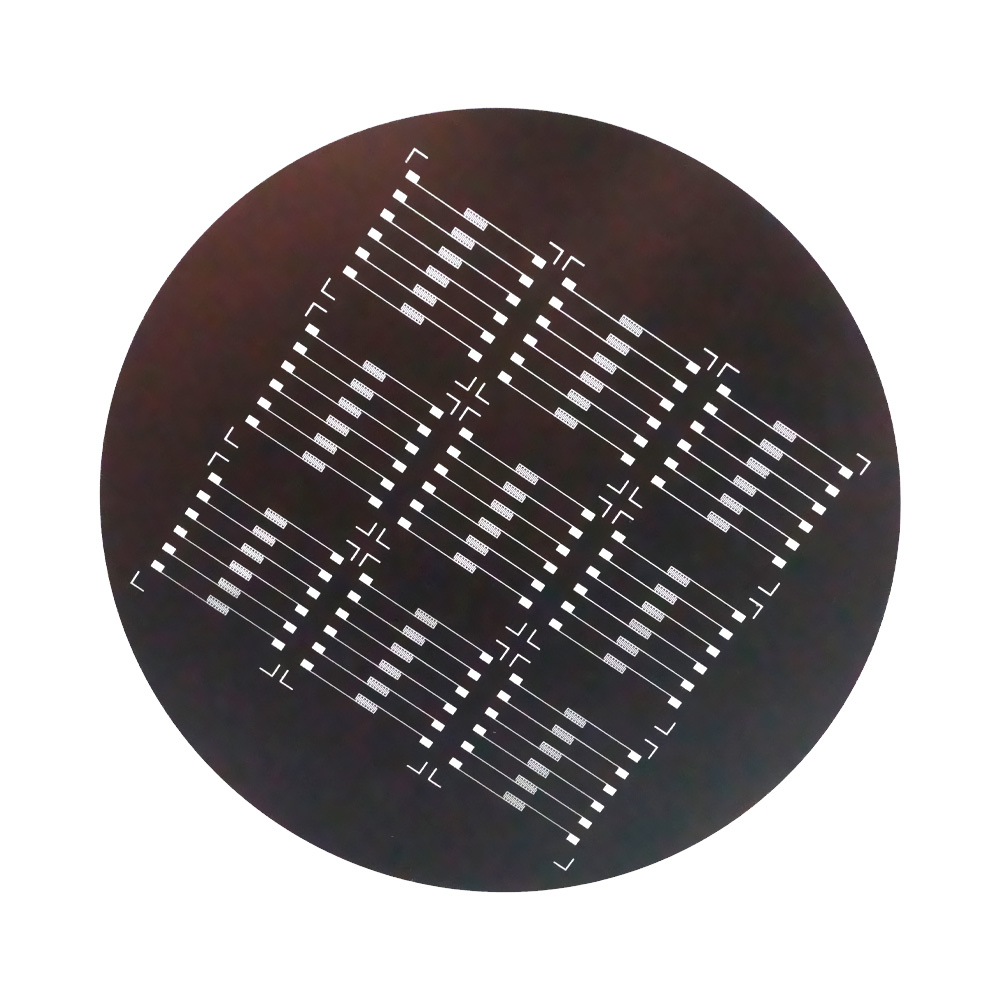

In cutting-edge technology fields such as biosensing, environmental monitoring, and electrochemical analysis, interdigital electrodes serve as core se...

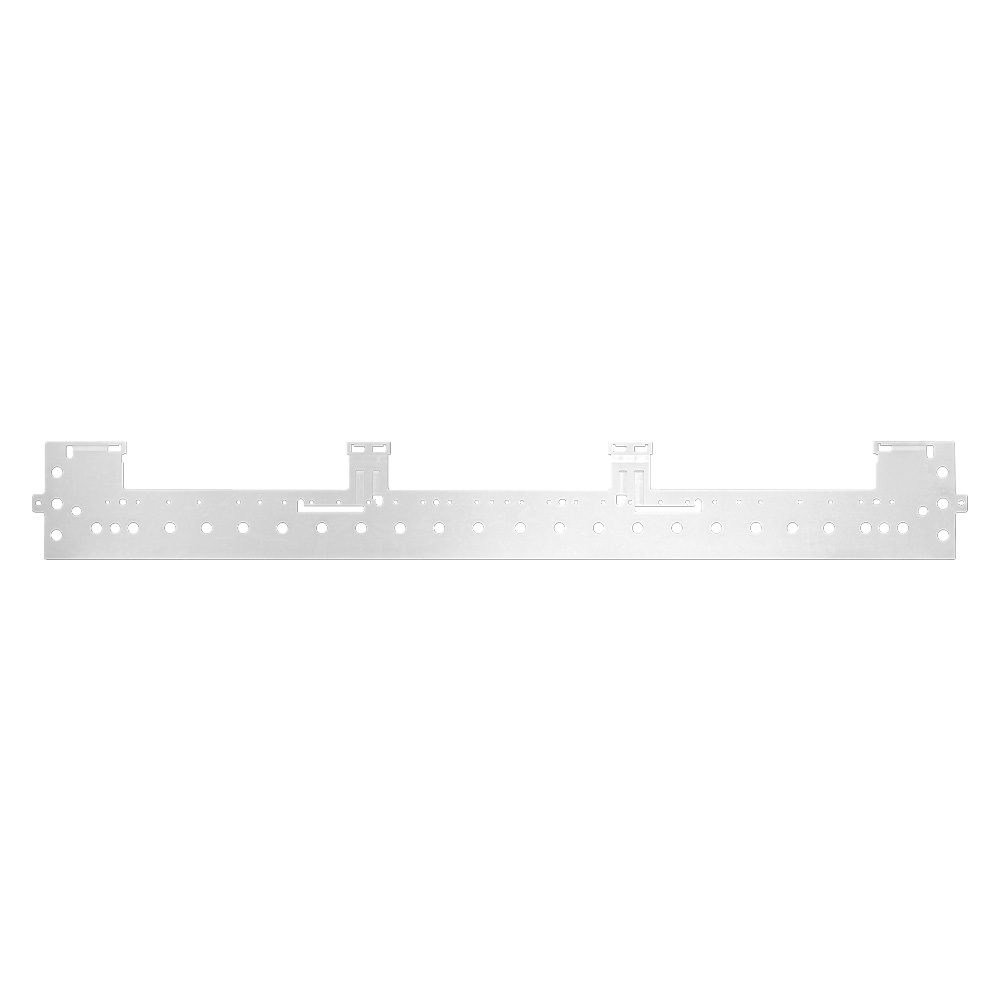

Magnetic carrier patches/covers are specially designed for the production and assembly of FPC flexible boards and PCBs, and are widely used in solder ...

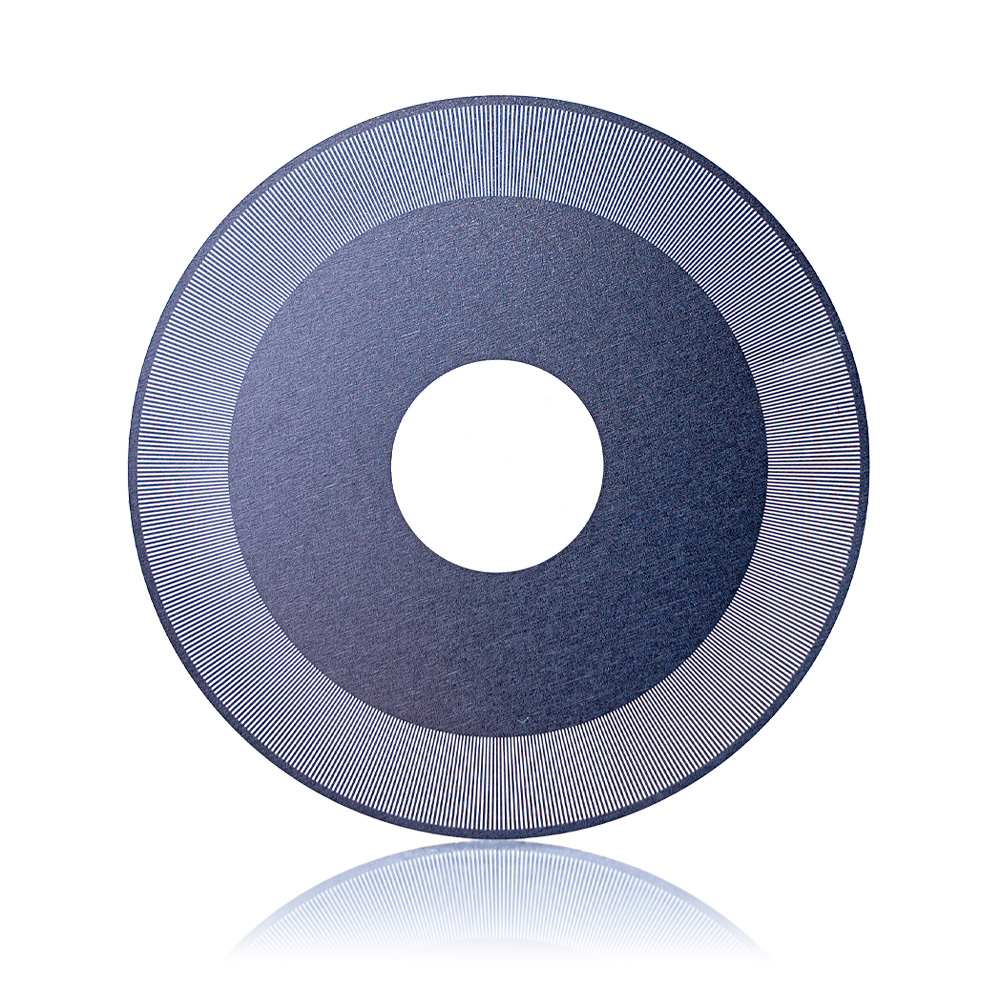

In the fields of industrial automation, high-end CNC machine tools, robots, servo motors, and precision instruments, accurate position detection and s...

Against the backdrop of lithium battery manufacturing entering the TWh era, improving production capacity, yield, and consistency has become the core ...

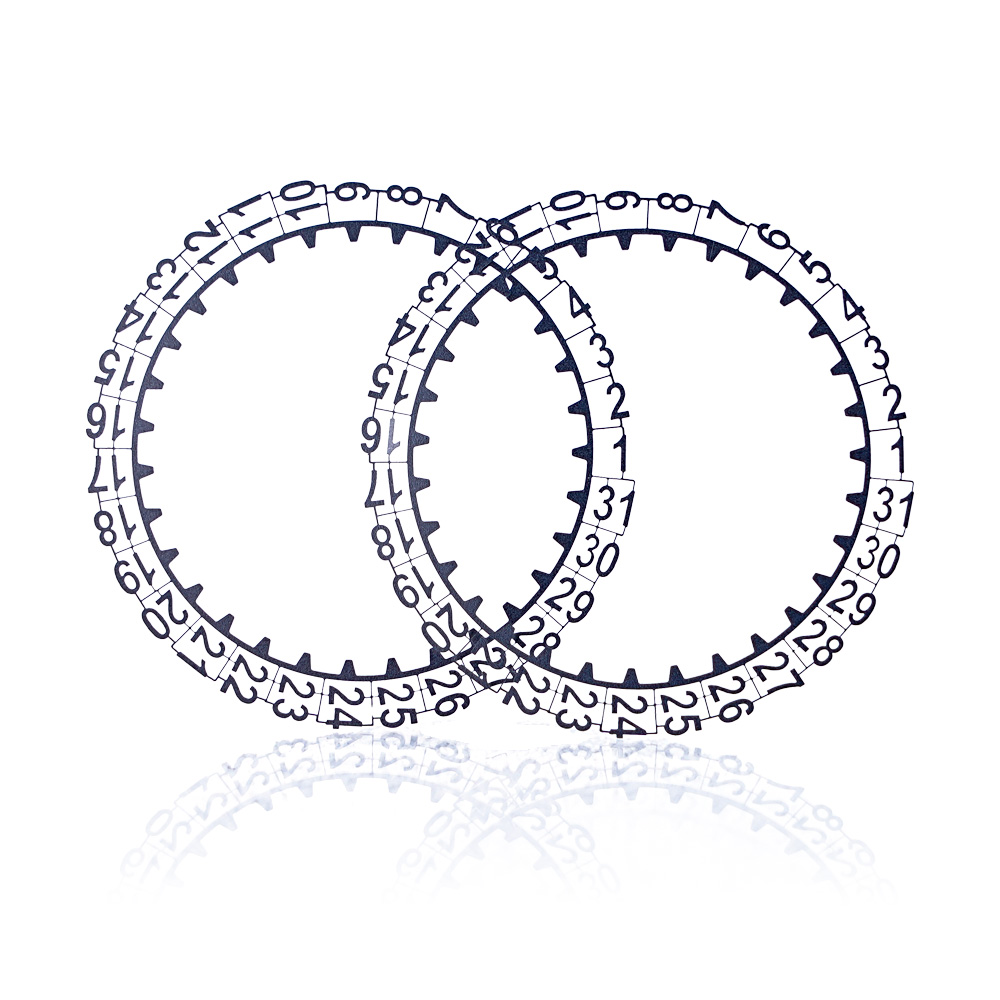

In the fields of high-end watchmaking and luxury jewelry, metal calendar rings are not only functional components for displaying dates, but also the i...

10 Years of Industry Technology Accumulation;

Two Manufacturing Bases (Dongguan & Vietnam).

Monthly Production Capacity Up to 9 Million Units;

Equipped with 55 Precision Laser Cutting Machines;

2 Polishing Production Lines;

Equipped with Multiple Laser Marking Machines, Laser Welding Machines, etc.

Providing One-Stop Solutions from Processing to Post-Treatment;

Supported Order Types: Small-to-Medium Batch Urgent Orders to Large-Scale Procurement;

Rapid Response: Sample Delivery as Fast as 3 Hours; Bulk Urgent Order Response Within 6 Hours.

Material Thickness: Focus on Precision Laser Cutting of 0.01mm to 3mm Thickness.

Processing Accuracy: Equipped with CCD Visual Positioning System, Achieving Ultra-High Precision of ±0.005mm to 0.02mm.

Minimum Hole Diameter: Up to 0.02mm.

Minimum Line Width: Up to 0.015mm.

Application Field: Meeting Processing Requirements of Precision Microstructures.

Core Components: Adopting German IPG Lasers to Ensure Energy Stability and Beam Quality from the Source, Achieving Smooth, Jagged-Free Cutting Contours.

Post-Treatment Process: Combined with Advanced Polishing Technology to Ensure Burr-Free Workpiece Surfaces and Enhance Final Texture.

Strictly Implementing ISO9001 Quality Management System.

End-to-End Coverage: Achieving Full-Process Control from Incoming Material Traceability to Finished Product Delivery.

Key Monitoring: Closely Monitoring Process Parameters Throughout Production.

Advanced Equipment: Equipped with KEYENCE Fully Automatic Projectors and Multiple 2D Projection Inspection Equipment.

Core Goal: Ensuring Product Quality Through Precision Inspection and Delivering On-Time with Qualified Quality.

Cooperation Mode: Assigning Exclusive Project Service Personnel for One-on-One Communication.

Demand Response: Accurately Understanding Customer Needs and Providing Preliminary Technical and Price Evaluations Within 1 Hour.

Providing Integrated Processing Services Including: Laser Cutting, CNC Machining, Laser Marking/Engraving, Laser Welding, Surface Treatment.

Processing Thickness: Covering Full-Spec Thickness from 0.01mm to 6mm.

Material Reserve: Over 30 Types of Metal Materials in Stock, Accurately Matching Diverse Manufacturing Needs.

Providing Full-Stage Support for Customers from Prototype Sampling to Large-Scale Procurement with Fast Delivery Guarantee.

Good Market Reputation Stems from Persistence in Quality

Providing Comprehensive Stainless Steel Laser Cutting and Automated Manufacturing Services for Customers

Changshan Precision integrates R&D, production, and sales of precision hardware products and magnetic steel sheet carriers

Dongguan Chanshan Precision Technology Co., Ltd Founded in 2017, with a workshop floor area of approximately 4,000 square meters, Chanshan Precision is headquartered in Dongkeng Town—located in the central part of Dongguan, Guangdong Province, within the Guangzhou-Shenzhen-Hong Kong economic corridor. As a high-tech enterprise specializing in high-precision micro-hole machining and laser cutting technology, we integrate R&D, production, and sales of precision hardware products and magnetic steel sheet carriers, dedicated to providing global high-end manufacturing enterprises with one-stop technical solutions to overcome complex component processing challenges.

Founded In

R&D Equipment

Team Members

Floor Area

![]() 400-8188-860

400-8188-860

![]() 130-3889-2257

130-3889-2257

Scan the QR Code

WeChat Official Account

Copyright © 2025 Dongguan Chanshan Precision Technology Co., Ltd. All Rights Reserved

Technical Support:sysx