![]() 2025-11-28

2025-11-28

![]() Changshan Precision

Changshan Precision

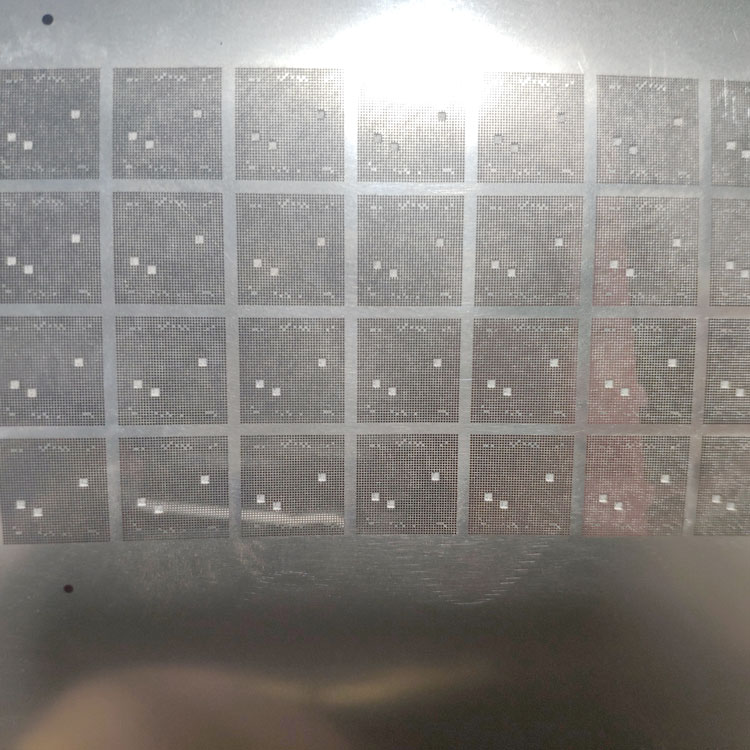

Micropores refer to pores with a diameter of less than 2 nanometers. Micropore processing is relatively challenging, especially for pores smaller than 1mm in diameter—traditional drilling equipment struggles to achieve such processing.

Amid these processing challenges, laser processing has come into focus. Laser technology is regarded as one of the indispensable tools for human survival and development in an intelligent society, with applications in hospital surgeries, industrial manufacturing, military training, and more. Among these, laser processing is one of the most promising fields of laser application.

Laser drilling machines in the laser field are high-tech products. Laser drilling utilizes the high power density (10⁶-10⁸ W/cm²) and excellent spatial coherence provided by pulsed lasers to ablate, vaporize, and evaporate the material at the irradiated area of the workpiece, achieving hole drilling. With an action time of only 10⁻³-10⁻⁵ seconds, laser drilling is extremely fast.

Micropore laser drilling is not limited by material properties such as hardness, brittleness, or softness—it can process nearly any material. It can drill holes without deformation in materials of any hardness, including steel plates, stainless steel, aluminum alloy plates, and cemented carbide. It can also create holes of arbitrary shapes or special configurations, enabling processes that conventional methods cannot achieve, such as drilling ultra-small holes smaller than 0.01mm.

Micropore laser drilling is a fully automated process. As a non-contact machining method, it requires no molds—the laser head does not come into contact with the material surface, eliminating the risk of workpiece scratches. Additionally, it features a small heat-affected zone (HAZ) and fast cooling speed, allowing 24/7 operation. It is suitable for high-density and batch drilling, thereby improving economic efficiency.