![]() 2025-11-28

2025-11-28

![]() Changshan Precision

Changshan Precision

In the traditional manufacturing sector, micropore processing has long been a challenge. For etched micropore processing, the primary materials used are metals, including 304 stainless steel, copper, and copper alloys.

When processing micropores in stainless steel, the following parameter requires attention: material thickness is a critical constraint for the etching process to effectively address micropore processing challenges.

Generally, the recommended pore diameter is 1.5 times the material thickness. If the pore diameter is smaller than this ratio, the etching method is not suitable for micropore processing, as the spreadability of current chemical etchants cannot meet the corrosion requirements.

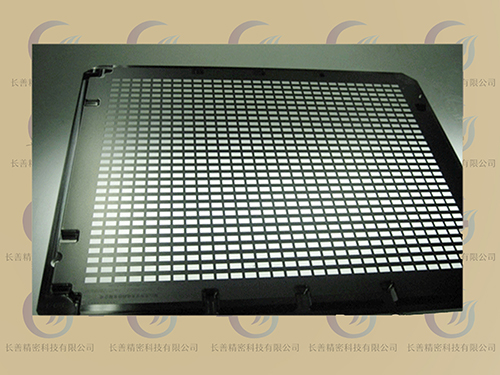

Today, micropore-processed products are widely used in precision filtration equipment.

Applications include chemical fiber spinnerets, jet engine nozzles, computer printheads, printed circuit boards (PCBs), TV baffles, planetarium star plates, aerospace gyroscope components, aircraft turbine parts, blades, and red blood cell filters in medical devices.

To date, there are more than 50 types of micropore processing methods, each with its own advantages and disadvantages. The selection primarily depends on factors such as workpiece pore size, hole arrangement, and density.

Other key considerations include pore precision requirements, subsequent workpiece applications, and which processes can support mass production.

Common conventional micropore processing methods include: Stamping – mainly used for products with a pore diameter of 1.0mm or larger and material thickness of 0.5mm or less. It is typically applied to workpieces with a small number of holes, as stamping dies cannot accommodate high-density hole arrangements.

CNC punching is a popular process in recent years, characterized by high processing efficiency.

Its advantages include low cost. CNC punching requires replacing corresponding punches for operation and does not need dedicated molds. It is mainly suitable for workpieces with large pore sizes and low hole density. CNC punching offers no advantages for workpieces with pore diameters smaller than 0.5mm.