![]() 2025-11-28

2025-11-28

![]() Changshan Precision

Changshan Precision

1. Electrical Discharge Machining (EDM) is a key component of micropore processing. EDM micropore technology has gained widespread attention with the continuous expansion of fields such as micromachinery, precision engineering, and optical instrumentation. With advantages including minimal cutting force during processing and adjustable pore diameter/depth via electrical parameters, EDM micropore processing has sparked growing research interest worldwide. However, EDM is typically a slow process—this limitation is particularly pronounced in micropore processing, where processing time increases as precision requirements rise. It is suitable for applications involving a small number of holes (e.g., around 2 or 5), primarily for tasks like mold drilling, but it cannot support mass production and comes with high costs.

2. Laser Processing is mainly suitable for materials with a thickness of less than 0.1mm and has been widely applied in the electronic industry. Examples include welding of precision electronic components, integrated circuit (IC) chip leads, and multi-layer circuit boards; drilling, scribing, and dicing of ceramic or gemstone substrates in hybrid integrated circuits; laser localized heating and annealing in semiconductor processing technologies; laser etching, doping, and oxidation; and laser chemical vapor deposition (LCVD). However, for metal micropore processing, laser technology has drawbacks: it may cause blackening, easily alter material properties, and leave residues that are difficult or impossible to remove. It is not a perfect micropore processing solution; it can be tried for applications with low requirements, but for bulk orders, laser processing fails to meet customers’ delivery time and cost expectations.

3. Wire Cutting adopts a continuous wire electrode feeding method—processing is completed as the wire electrode moves. Even if wire electrode wear occurs, it can be continuously replenished, thereby improving part processing accuracy. Workpieces processed by Slow Wire Electrical Discharge Machining (SWEDM) typically achieve a surface roughness of Ra=0.8μm or better. Additionally, SWEDM outperforms Fast Wire Electrical Discharge Machining (FWEDM) significantly in terms of roundness error, straightness error, and dimensional error, making it widely used for processing high-precision parts. However, for micropore processing, the wire cutting process tends to cause material deformation; it cannot cope with mass production and is expensive, making it generally unacceptable to customers.

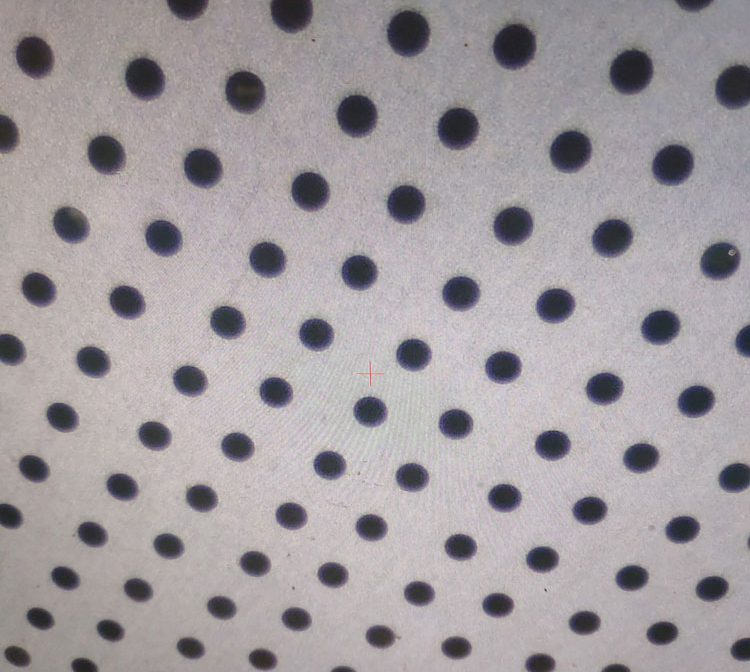

4. Etching, also known as photochemical etching, involves removing the protective film from the areas to be etched after exposure and development. During etching, the workpiece contacts chemical solutions, and two positive patterns are used to achieve dissolution through chemical grinding from both sides, resulting in concave-convex or hollowed-out forming effects. Etching is highly targeted and refers to controlled corrosion—a controllable processing method for metals using chemical means. With the development of electronic technology, there is an increasing demand for ultra-thin workpieces with complex geometric shapes and high precision that are difficult to achieve through mechanical processing. In contrast, chemical etching can easily meet the requirements of flat, burr-free components with complex patterns, while offering a short processing cycle and low cost. Its chemical principle relies on ferric chloride aqueous solution acting as a corrosive agent to react with metals.

5. Micro-Drilling: Generally speaking, drills with a diameter of less than 3.175mm can be referred to as micro-drills, which are likely familiar to most. The key to melt-blown die heads lies in micropore processing—their pore diameters range from Ф0.1mm to Ф0.3mm, with an aspect ratio (depth-to-diameter ratio) exceeding 10, posing certain processing challenges.